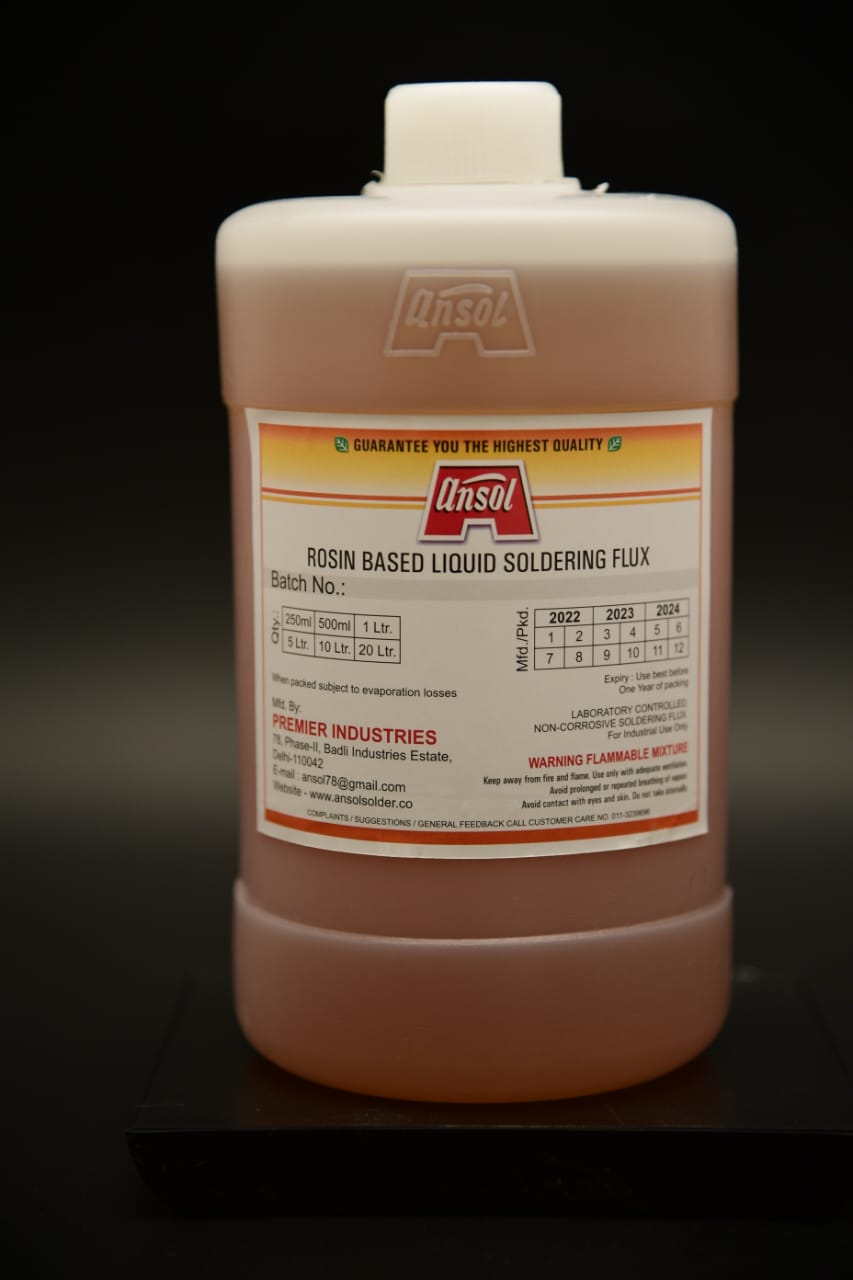

Liquid Soldering Flux

Liquid Soldering Flux Specification

- Operating Temperature

- 180 Celsius (oC)

- Application

- Industrial

- Usage

- in wave, selective and hand soldering processes

- Size

- 250ml-20 ltr

- Product Type

- Liquid Soldering Flux

- Color

- Light yellow

Liquid Soldering Flux Trade Information

- Minimum Order Quantity

- 100 Liters

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 5000 Liters Per Month

- Delivery Time

- 2 Days

- Packaging Details

- 500 mL, 1 L, 51 L, 101 L, 201 L, 2001 L

- Main Export Market(s)

- North America, Middle East, Western Europe, Africa, Central America, Eastern Europe, South America, Asia, Australia

- Main Domestic Market

- All India

- Certifications

- ISO 9001: 2008 Certified Company

About Liquid Soldering Flux

We are one of the trusted suppliers, exporters and manufacturers of Liquid Soldering Flux to our widely spread clients. It is halogen-free,low solids solvent system designed for wave soldering,conventional and surface mount circuit board assemblies. It can be applied by foaming, spraying, dipping or brushing. The low solids content and the properties of activators system of the fluxes require no-cleaning after soldering. The non corrosive and non-conductive residue of the Liquid Soldering Fluxusually have high insulation resistance. It is ideal for low-temperature and high-temperature re flow, leaded and lead-free alloys in various flux types and alloy particle sizes. These are widely appreciated by our clients in both domestic as well as international markets for optimum quality, leading to highly increasing demands among our competitors.

Ansol #NC-108

(low Solid Rosin No Clean)

General Information:

ANSOL #NC-108 Flux is a solution of high quality, purified rosin and extremely effective and is non- corrosive accordance with the strict requirement of specification DIN. ANSOL #NC-108 Flux provides good electrical insulation with its protective resinous formulation and special activating agent give consistently good soldering results. ANSOL #NC-108Flux can be used for both conventional through hole, SMD Soldering and dip too. The low solid contents of this flux has the advantages of leaving lesser amount of residue on the board after soldering without compromising on the good soldering results.

Ansol#NC-02 Flux

(no Clean Flux)

General Information:

ANSOL#NC-02FLUX is a solution of high quality, chemical and extremely effective and non-corrosive in accordance with the strict requirement of specification DIN. ANSOL#NC-02FLUX has high surface Insulation Resistance and does not cause any electromigration. Therefore, be used for No Cleaning Application. ANSOL#NC-02FLUX is an environment friendly, halide free, low residue for wave soldering of through-hole, mixed technology and surface mount assemblies.

Ansol#NC-07 Flux

(no Clean Flux)

General Information:

ANSOL#NC-07FLUX is a solution of high quality, chemical and extremely effective and non-corrosive in accordance with the strict requirement of specification DIN. ANSOL#NC-07FLUX has high surface Insulation Resistance and does not cause any electromigration. Therefore, be used for No Cleaning Application.

Ansol#NC-08 Flux

(no Clean Flux)

General Information:

ANSOL#NC-08FLUX is a solution of high quality, chemical and extremely effective and non-corrosive in accordance with the strict requirement of specification DIN. ANSOL#NC-08FLUX has high surface Insulation Resistance and does not cause any electromigration. Therefore, be used for No Cleaning Application.

| Model Name/Number | Ansol Soldering flux |

| Material Composition | Liquid Flux |

| Is It Inflammable | Yes |

| Packaging Size | 500 mL, 1 L, 51 L, 101 L, 201 L, 2001 L |

| Brand | ansol |

| Contains Rosin | Yes |

| Packaging Type | plastic jar |

| Usage/Application | Soldering Flux |

| Material Type | liquid |

| Weight | 1 Ltr |

Versatile Soldering Solution

Our flux adapts to diverse soldering environments, offering seamless integration with wave, selective, and manual soldering applications. Its stable formulation ensures consistent flow, improved wetting, and reduced soldering imperfections across various industrial requirements.

Optimized for Performance

Crafted to perform at an operating temperature of 180C, this flux enhances thermal stability and solder joint reliability. The light yellow color serves as an indicator for uniform application, assisting users in achieving high-quality results with each use.

Flexible Packaging for Every Need

Available in container sizes from 250 ml up to 20 liters, our liquid soldering flux accommodates the distinct demands of small workshops and large production lines alike, allowing for precise inventory management and reduced wastage.

FAQs of Liquid Soldering Flux:

Q: How should Liquid Soldering Flux be applied in industrial settings?

A: Liquid Soldering Flux is typically applied directly onto the surfaces to be soldered, either manually with a brush or automatically via fluxing systems in wave and selective soldering machines. Ensure surfaces are clean for optimal results.Q: What processes is this flux suitable for?

A: This flux is engineered for use in wave, selective, and hand soldering processes, making it highly versatile for various electronic assembly and production tasks.Q: When is the ideal operating temperature for using this soldering flux?

A: For best performance, this flux should be used at its rated operating temperature of 180C, which ensures optimal activation and solder joint integrity.Q: Where can this flux be purchased or supplied from?

A: We are an established exporter, manufacturer, and supplier based in India, supplying the product to domestic markets and international clients through authorized distributors and direct sales channels.Q: What is the benefit of the light yellow color in this soldering flux?

A: The light yellow color assists in visually verifying the flux application during the soldering process, aiding in quality control and helping to ensure even coverage.Q: How does using this liquid flux improve the soldering process?

A: This flux enhances solder wetting, reduces oxidation, and promotes the formation of robust, reliable joints, which minimizes defects and improves overall production quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Soldering Fluxes Category

Rosin Liquid Flux

Minimum Order Quantity : 100 Liters

Usage : electrical soldering

Size : all size

Product Type : Rosin Based Soldering Flux

Application : Industrial

Aluminium Soldering Flux

Minimum Order Quantity : 1 Piece

Usage : soldering or brazing aluminum and aluminumbased alloys.

Size : all size

Product Type : Aluminium Soldering Flux

Application : Industrial

Color : Transparent

Aluninium Soldering Flux

Minimum Order Quantity : 100 Liters

Usage : Electronics

Size : Standard

Product Type : Aluninium Soldering Flux

Application : Industrial

Color : Red

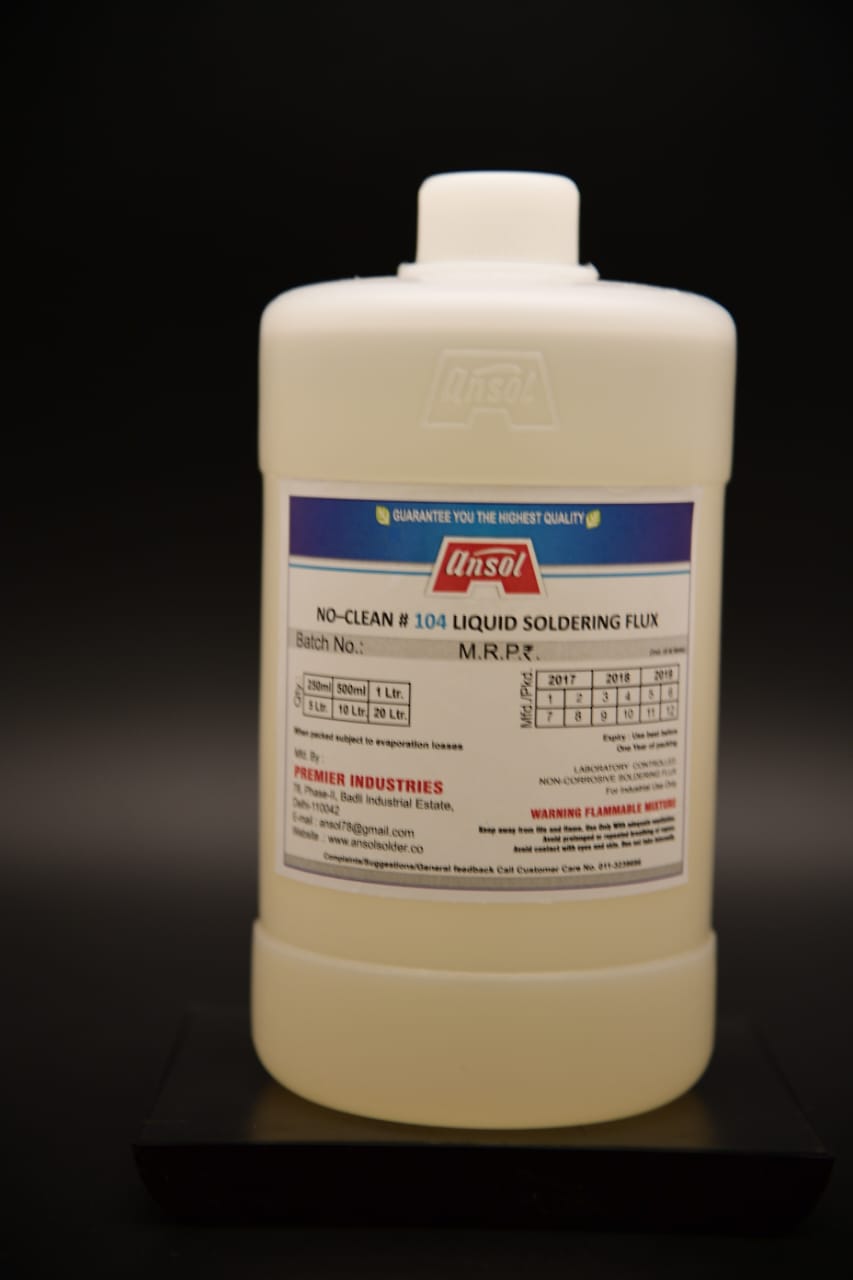

No Clean 104 Soldering flux

Minimum Order Quantity : 100 Liters

Usage : Electronics

Size : 250ml20 ltr

Product Type : No Clean 104 Soldering flux

Application : Industrial

Color : Colourless

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry